Solutions to heat dissipation problems in stage lighting?

Stage lighting is widely used in all aspects of today's society and brings a lot of fun to people's lives. At the same time, the problem of how to dissipate heat inside the stage lighting becomes more and more obvious.

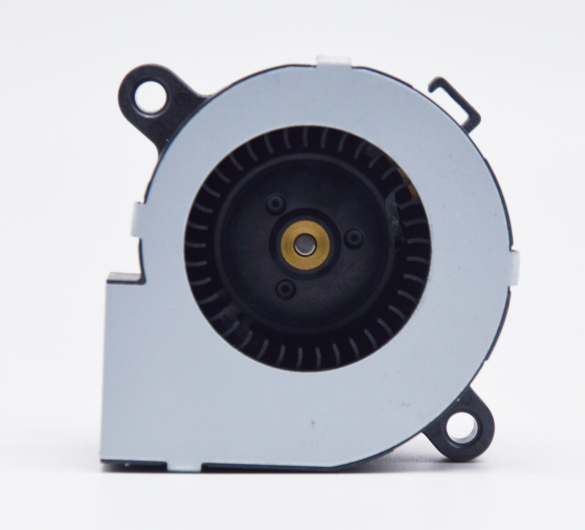

It should be known that the light source of the beam lamp is a heat source, and the consequences can be imagined when the power is too large and flammable materials are encountered. When the temperature inside the lamp is too high, the first thing that comes to mind is heat dissipation. General purpose fans for stage lights are DC blowers (such as 5025, 7530)

5025 high temperature blower 7530 high temperature blower

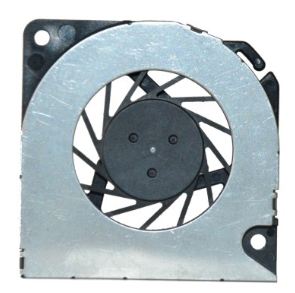

And DC box fans (8025, 9225).

8025 DC fan 9225 DC fan

The combination of the two will significantly improve the heat dissipation effect in the lamp housing. The principle of the lighting DC fan is: the heat generated by the lamp is conducted through physical contact with the radiator made of high thermal conductivity material (exhaust the internal hot air to the outside of the lamp housing, so that the external cold air enters the inside of the lamp housing) This kind of high thermal conductivity material is generally aluminum. Because of its light weight, low price and easy production, it is the basic material for making lamp radiators. In order to conduct heat to the radiator as much as A high thermal conductivity medium is potted between the radiators for heat conduction. The thermal conductivity medium used between the LED device and the radiator is generally silicone thermally conductive potting glue, which can effectively improve the LED The heat dissipation capacity of the bulb lamp, and also has excellent protective performance, has good salt spray, moisture resistance and weather resistance, especially in the performance of resistance to temperature shocks, which is unmatched by other potting glues. It can be used in- Long-term use under the condition of 60℃~200℃.

The basic working principle of DC fan is to use DC motor and AC motor type motors in different ways. The DC fan motor is controlled by a computer, the power supply voltage is +12 V, and the speed ranges from 1000 to 10000 rpm. A rotating machine that converts electrical energy from a DC fan into mechanical energy. It consists of a three-part stator, a rotor and a commutator. There are more than two rotor coils, and a magnet wound by a wire is called a winding. When the current passes through the windings, the magnetic field produces the force generated by the magnetic field and the stator magnetic field.

Since the stator is fixed, the rotor can continuously rotate by the force generated by the magnetic field and the stator magnetic field. The DC motor of the commutator is a special device in which there are multiple commutator segments, and every two adjacent commutator segments are insulating intermediate pieces. The commutator fixes the surface of the spring-loaded brush, and the rotatable armature winding is connected to the external circuit. When the rotor rotates a certain angle, the commutator, connected with the power supply voltage to another winding, the winding generates a magnetic field. Due to the existence of the commutator, the armature coil passing the electromagnetic torque remains unchanged, and the rotor of the DC fan starts to move under the action of the electromagnetic torque of the armature.

Due to the relatively harsh environment in which stage light locks are used, ordinary DC fans on the market cannot be used for internal heat dissipation, but relatively high-end DC cooling fans should be used. High-end fans generally use more advanced liquid bearings to improve the stability and reliability of the fans, thereby increasing the service life of the client stage lights.

Dongguan Yinhai Electronics Co., Ltd. (www.yinhaidg.com) is an enterprise focusing on fan R&D and production. At present, it is deeply engaged in the stage lighting industry. Because of its focus, it is professional. At present, the company has a professional R&D team. Can provide you with an integrated stage lighting cooling system solution! Please indicate the source!

中文

中文 English

English